Nel campo del miglioramento delle prestazioni e della fisioterapia, gli atleti vedono spesso sui loro corpi il nastro kinesiologico, noto anche come nastro terapeutico elastico. Dal nastro all'ossido di zinco per il ginocchio al nastro muscolare atletico colorato e flessibile, questo elemento essenziale è parte integrante dell'attrezzatura sportiva.

Ma come viene realizzato e commercializzato un prodotto così ampiamente utilizzato dai campioni olimpici, dagli appassionati di fitness e dai fisioterapisti di tutto il mondo? Viene prodotto da fornitori professionali di nastri kinesiologici, venduto da rivenditori e distributori e infine arriva nelle nostre mani.

Come trovare un produttore professionale di nastri kinesiologici

Trovare i fornitori di nastri kinesiologici più adatti alle vostre esigenze non riguarda solo il prodotto in sé, ma anche le capacità e il servizio offerto dalla fabbrica. Una ricerca su Google Chrome fornisce una grande quantità di informazioni di base:

I principali centri di produzione di nastri kinesiologici sono concentrati principalmente in Cina (Jiangsu, Zhejiang e Anhui) e Corea del Sud. Inoltre, esistono produttori locali in Nord America (Stati Uniti e Canada) ed Europa (Germania), che spesso realizzano prodotti specializzati o di alta gamma.

Principali aziende/fornitori: Tra questi figurano grandi marchi globali (3M, Mueller, KT Tape e RockTape) nonché importanti OEM/fornitori cinesi e coreani (Wuxi Wemade, GSPMED, Aupcon, Suzhou SunMed e THYSOL/CureTape).

Tipi di prodotti: Nastro kinesiologico (elastico), nastro all'ossido di zinco (non elastico), benda coesiva (alta elasticità) e nastro adesivo per il seno, tra gli altri.

Certificazioni: Offriamo prodotti di alta qualità (certificazioni ISO, CE e FDA), servizi personalizzati (marchio privato e OEM/ODM), prezzi competitivi e logistica efficiente.

Analisi della produzione di nastro kinesiologico e nastro all'ossido di zinco

Diversi tipi di nastro adesivo sportivo—nastro kinesiologico (cotone elastico/sintetico misto fibre) e Nastro sportivo in ossido di zinco (cotone non elastico/ossido di zinco) — richiedono processi di produzione diversi, ma entrambi necessitano di un elevato grado di precisione.

Fase 1: Approvvigionamento e preparazione delle materie prime

Le prestazioni di un nastro dipendono dai suoi due componenti principali: il tessuto di supporto e l'adesivo.

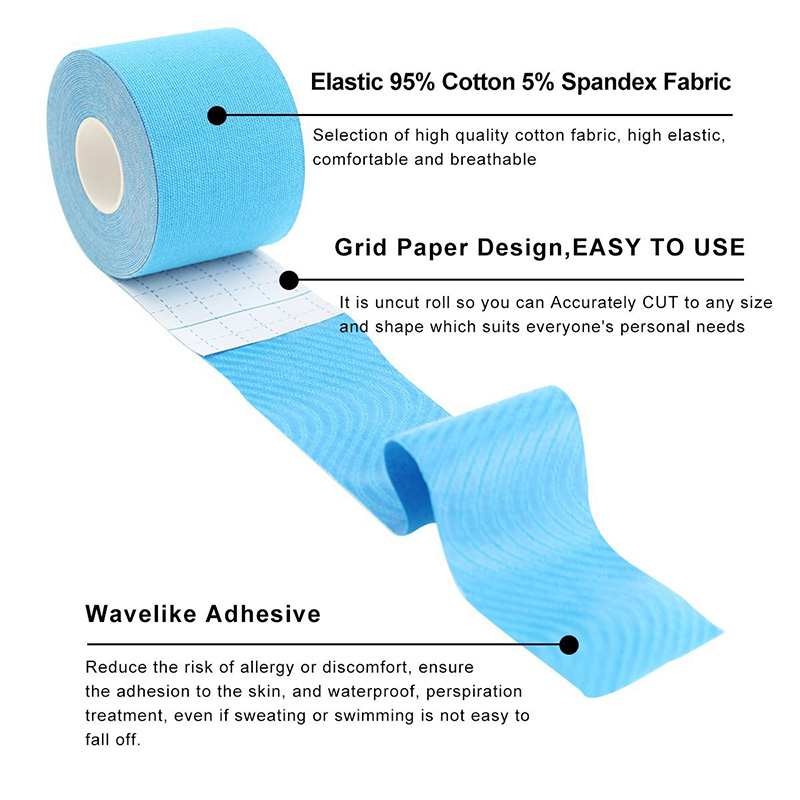

Tessuto: Il nastro sportivo all'ossido di zinco utilizza solitamente un tessuto di cotone puro ad alta resistenza. Il nastro kinesiologico, invece, è solitamente realizzato in cotone/spandex o in una miscela di fibre sintetiche progettata per imitare l'elasticità della pelle umana (con un allungamento fino a 140-180%).

Adesivo: Questo è l'elemento più importante. La maggior parte dei moderni nastri atletici utilizza un adesivo acrilico ondulato di grado medico. L'ossido di zinco è comunemente usato anche nei nastri sportivi rigidi per la sua resistenza e le sue lievi proprietà antimicrobiche, e i produttori di alta qualità danno la priorità a formulazioni ipoallergeniche e prive di lattice.

Fase 2: Processo di rivestimento e polimerizzazione

Questa è la fase effettiva di produzione del nastro. Il tessuto di supporto viene inserito in un ambiente controllato su larga scala dove viene applicato l'adesivo.

Applicazione: L'adesivo viene applicato con precisione su un lato del tessuto. Il nastro kinesiologico presenta spesso un caratteristico motivo ondulato per massimizzare la traspirabilità e la mobilità della pelle.

Polimerizzazione: Il tessuto rivestito viene quindi inserito in una camera di essiccazione o polimerizzazione specializzata. Questo processo è fondamentale, poiché la temperatura e il tempo devono essere calibrati con precisione per garantire che l'adesivo polimerizzi correttamente, fornendo un forte legame e senza lasciare residui appiccicosi una volta rimosso.

Taglio e avvolgimento: Dopo l'essiccazione, i grandi rotoli di materiale vengono inseriti in macchine da taglio ad alta precisione. Queste macchine tagliano i giganteschi “rotoli madre” nelle larghezze richieste dal consumatore finale (ad esempio, 5 cm, 3,8 cm), che vengono poi avvolti su anime di cartone.

Analisi della forza dei fornitori di nastri kinesiologici

Controllo qualità e certificazione

Questa fase è essenziale per qualsiasi fornitore affidabile di nastri kinesiologici. I controlli di qualità includono:

Prova di adesione: Misurazione della resistenza allo strappo del nastro.

Resistenza allo strappo: Testare la resistenza alla trazione del cotone/rayon per garantire che possa sostenere la cucitura.

Test di irritazione cutanea: Garantire che l'adesivo sia sicuro per un contatto prolungato.

I fornitori affidabili di nastri kinesiologici sono in genere in possesso di certificazioni quali ISO 13485 (Sistemi di gestione della qualità per dispositivi medici), marchio CE (per il mercato europeo) e registrazione FDA (per il mercato statunitense). Queste certificazioni dimostrano l'impegno dell'azienda a garantire una qualità di livello clinico.

L'evoluzione della catena di approvvigionamento

Dalla fabbrica alle mani dei consumatori. Il mercato dei nastri adesivi sportivi sta attualmente registrando una forte crescita, trainata da diverse tendenze moderne che stanno ridefinendo il modo di operare dei fornitori di nastri adesivi sportivi. Si prevede che il mercato globale dei nastri adesivi sportivi continuerà la sua traiettoria di crescita positiva, con dati che indicano una forte domanda nel prossimo decennio.

Conclusione

Lavorare direttamente con fornitori di nastri kinesiologici di alta qualità è una decisione strategica. Si tratta di un investimento in una partnership che offre i seguenti vantaggi:

Qualità superiore: Garantisce che ogni prodotto che esce dalla fabbrica sia resistente e duraturo.

Ottimizzazione dei costi: Riduce il costo totale di proprietà abbassando i prezzi unitari e minimizzando le interruzioni della produzione.

Fornitura: Crea un flusso di materiali prevedibile e trasparente.

Vantaggio competitivo: Sfrutta la personalizzazione per creare prodotti unici e distinguersi sul mercato.

Se stai cercando un prodotto di alta qualità fornitori di nastro kinesiologico, Aupcon soddisfa pienamente questi requisiti. Abbiamo una forte presenza sul mercato nazionale e una solida reputazione, offrendo servizi OEM/ODM. Offriamo un'ampia gamma di prodotti di nastri atletici, tra cui nastro kinesiologico in cotone, nastro kinesiologico pretagliato, nastro all'ossido di zinco, nastro per le dita, nastro adesivo per campi da calcio in erba sintetica, pre-deformazione, e altro ancora. Per ulteriori informazioni, contattateci per richiedere il catalogo dei prodotti. Saremo lieti di collaborare con voi.